Keeping Your Albany Industry Running Smoothly: Industrial Insulation Services by Albany Spray Foam Solutions

In the fast-paced world of Albany’s industrial sector, maintaining optimal operational efficiency is paramount. This includes ensuring a well-regulated building environment that minimizes energy waste and maximizes comfort for employees. Here’s where industrial insulation services by Albany Spray Foam Solutions come into play.

We understand the unique needs of Albany’s industrial facilities. Our team of certified and experienced professionals specializes in providing top-tier spray foam insulation solutions specifically designed for industrial applications. By effectively insulating your industrial buildings, you can achieve a multitude of benefits, translating into significant cost savings and a more productive work environment.

What are Industrial Insulation Services?

Industrial insulation services involve applying specialized insulation materials to various components within an industrial building. This can include walls, ceilings, roofs, pipes, ducts, and vessels. The primary purpose of industrial insulation is to:

- Reduce energy consumption: By creating a thermal barrier, spray foam insulation minimizes heat transfer, leading to lower heating and cooling costs.

- Maintain consistent temperature: Proper insulation helps regulate indoor temperatures, ensuring a comfortable and productive work environment for employees while optimizing process control for sensitive equipment.

- Prevent condensation: Insulation helps prevent condensation on pipes and ducts, which can lead to corrosion and mold growth. This translates to reduced maintenance costs and improved equipment longevity.

- Enhance noise control: Certain spray foam insulation types offer superior soundproofing capabilities, reducing noise pollution within the facility.

- Improve fire safety: Some spray foam formulations possess fire-retardant properties, adding an extra layer of safety to your industrial space.

Why Choose Albany Spray Foam Solutions for Your Industrial Insulation Needs?

At Albany Spray Foam Solutions, we go beyond simply offering industrial insulation services. We take pride in partnering with our clients to understand their specific needs and develop customized solutions that deliver optimal results. Here’s what sets us apart:

- Experienced and Certified Team: Our installers are highly trained and certified in the latest spray foam application techniques, ensuring a safe and efficient installation process.

- High-Quality Materials: We utilize only the highest-quality spray foam products from industry-leading manufacturers, guaranteeing long-lasting performance and durability.

- Safety First: We prioritize safety throughout the entire project, adhering to strict safety protocols and industry best practices.

- Commitment to Efficiency: We work diligently to minimize disruption to your operations, ensuring a smooth and efficient installation process.

- Competitive Pricing: We offer competitive pricing for our industrial insulation services, ensuring you receive exceptional value for your investment.

Benefits of Spray Foam Insulation for Industrial Applications

Spray foam insulation offers several advantages over traditional insulation materials for industrial settings:

- Superior Insulative Value: Spray foam boasts a higher R-value per inch compared to other insulation materials, meaning it provides superior thermal resistance with a thinner application.

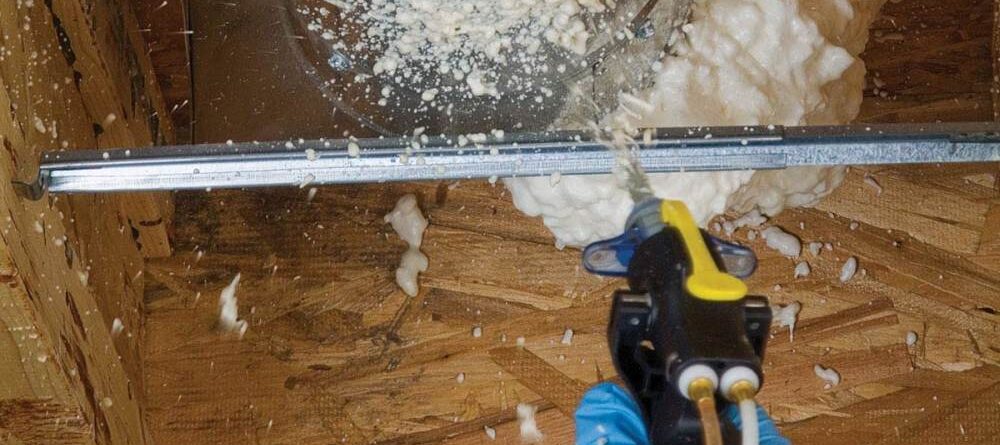

- Seamless Application: Spray foam fills all cracks, gaps, and voids, creating a continuous and airtight seal, significantly reducing air infiltration.

- Moisture Resistance: Spray foam is highly resistant to moisture, preventing condensation and mold growth.

- Lightweight Material: Spray foam adds minimal weight to building structures, making it ideal for existing facilities.

- Long-lasting Performance: Spray foam insulation retains its insulating properties for decades, offering a long-term return on investment.

Investing in Industrial Insulation:

By investing in industrial insulation services from Albany Spray Foam Solutions, you’re making a wise decision for your business. Here are some of the key advantages you can expect:

- Reduced Energy Costs: Proper insulation can significantly lower your heating and cooling energy consumption, leading to substantial cost savings over time.

- Improved Comfort: A well-insulated building provides a more comfortable and controlled working environment for your employees, potentially boosting productivity and morale.

- Enhanced Equipment Performance: Consistent temperatures help ensure optimal performance of your industrial equipment, minimizing downtime and maintenance needs.

- Increased Building Value: Proper insulation can add value to your industrial property by making it more energy-efficient and desirable for potential buyers or tenants.

FAQs

1. What types of industrial facilities can benefit from spray foam insulation? Spray foam insulation is suitable for a wide range of industrial facilities, including warehouses, manufacturing plants, processing facilities, power plants, and cold storage facilities.

2. How long does the installation process typically take? The installation timeframe depends on the size and complexity of your industrial building. Our team will provide a detailed estimate during the initial consultation.

3. Is spray foam insulation safe for industrial applications? When installed correctly by certified professionals, spray foam insulation is safe for industrial use. We utilize closed-cell spray foam formulations, which are non-toxic and emit minimal VOCs (volatile organic compounds).

4. How do I maintain spray foam insulation? Spray foam insulation requires minimal maintenance. Regular inspections for any damage or tears are recommended. For optimal performance, it’s advisable to have the insulation cleaned professionally every few years, depending on the environment.

5. What is the cost of industrial spray foam insulation? The cost of industrial spray foam insulation varies depending on several factors, including the size and complexity of your building, the chosen spray foam type, and the thickness required. Our team will assess your specific needs and provide a detailed quote during the consultation.

Conclusion

Investing in industrial insulation services by Albany Spray Foam Solutions is a strategic decision that pays off in the long run. By optimizing your building’s energy efficiency, you can create a more comfortable work environment for your employees, enhance equipment performance, and significantly reduce energy costs. With our expertise, high-quality materials, and commitment to safety, we ensure a smooth and efficient installation process that minimizes disruption to your operations.

Call to Action (CTA): Ready to take control of your industrial facility’s energy consumption and create a more productive environment? Contact Albany Spray Foam Solutions today! Call us at (518) 378-0740 or email us at joey@albanysprayfoamsolutions.com to discuss your specific industrial insulation needs. Visit our website at https://albanysprayfoamsolutions.com/ to learn more about our services.

At Albany Spray Foam Solutions, we’re committed to helping Albany’s industrial sector operate at peak efficiency. Let’s work together to create a more sustainable and cost-effective future for your business.

Leave a Reply